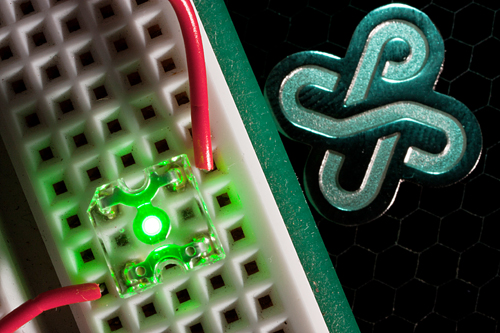

Local startup Pacific Light Technology recently got $3 million to start research on LED light technology. Currently partnered with Portland State’s Business Accelerator, the lab and office space provided will help Pacific Light to develop technology that will lead to more efficient and less expensive LED lights.

PSU facility provides space for LED light research

Local startup Pacific Light Technology recently got $3 million to start research on LED light technology. Currently partnered with Portland State’s Business Accelerator, the lab and office space provided will help Pacific Light to develop technology that will lead to more efficient and less expensive LED lights.

Most of the $3 million came from the Oregon Angel Fund and Pivotal Investments. Later this year, PLT plans to go into another round of funding and come out with $4–8 million to help start manufacturing. Pacific Light started in April 2011 and began the Business Accelerator in June. It is a materials company that primarily focuses on making materials to go into LED lights.

Currently, PLT is working to develop a material that will improve LED light quality. They will have a better color, mainly a better white light.

“Right now, the reason people don’t necessarily buy LED lights is because they don’t like the color—it looks too blue to them, and they are too expensive. They’re like $25, and you can buy an incandescent for almost $1,” said Juanita Kurtin, Pacific Light chief technology officer. “So our material will make the color quality something that is more pleasing to the eye, and it will do that at a better efficiency, so the bulb should be less expensive.”

In general, LED lights last much longer than the average household light bulb, using less electricity, so they are environmentally friendly while also bringing down the electricity bill. They are expensive, but Pacific Light expects to be able to sell the new bulb for about half the price of today’s cost.

Ron Nelson, CEO of Pacific Light, was out of town and unable to speak to Vanguard staff prior to publication. In a press release issued on PSU’s website, Nelson said that Pacific Light plans to eliminate the use of phosphors in LED lights and replace it “with ‘quantum dots’—chemically created microscopic semiconductors.” These are what help the LED lights have a more eye-friendly color.

Partnering with PSU’s Business Accelerator allowed Pacific Light to access vital space and equipment necessary to work on developing the LED materials. “Often times these collaborations allow startup companies access to scientific equipment they cannot afford to buy and consulting by highly qualified faculty at PSU,” said Tony Chen, manager at the Center for Electron Microscopy and Nanofabrication, which works closely with PLT.

The center is a core research laboratory at PSU used by many people and is a signature facility of Oregon Nanoscience and Microtechnologies Institute. Chen said they support the technology and product development of PLT by providing them with state of the art equipment and employee training.

CEMN’s support of PLT goes right along with its mission, which is “to support faculty research, education and collaboration with industry partners that fosters economic development in Oregon.”

The Center helps researchers seek answers to a number of questions they may have regarding their research: What does a material look like at the nano scale, how big is it, what is the size distribution, what elements are present, are there defects in manufacturing and many others along those lines.

But ultimately, a big part of CEMN is its relationship with PSU.

“The economic development and education work at CEMN helps PSU students have job opportunities upon graduation,” Chen said.

Kurtin said that besides its use of the center’s resources, Pacific Light also hires some PSU students to help as lab technicians in its research.

Chen said that projects like Pacific Light’s and other companies using the Business Accelerator are greatly beneficial to PSU and society in general. They help PSU students “gain direct knowledge of nanotechnology and nanofabrication from real-world industrial applications,” Chen said.

Students are able to get a better idea of what a career in that field would be like and to help prepare them for future careers in nanotechnology and other emerging technologies. It also greatly enhances the partnership of university research and industrial innovation, which helps the Portland community by providing future employment opportunities for PSU graduates.